SP 3-872-009 Shut Down Harness

Introduction

In the world of electrical and mechanical systems, safety and efficiency are paramount. One essential component that plays a crucial role in the functionality of industrial and automotive machinery is the SP 3-872-009 Shut Down Harness. This specialized harness is designed to provide a fail-safe mechanism, ensuring the safe operation of machinery by effectively shutting down electrical circuits when necessary.

In this article, we will explore the details of the SP 3-872-009 Shut Down Harness, its purpose, applications, benefits, and troubleshooting methods. Whether you are an engineer, technician, or enthusiast looking to understand more about this essential component, this guide will provide you with comprehensive insights.

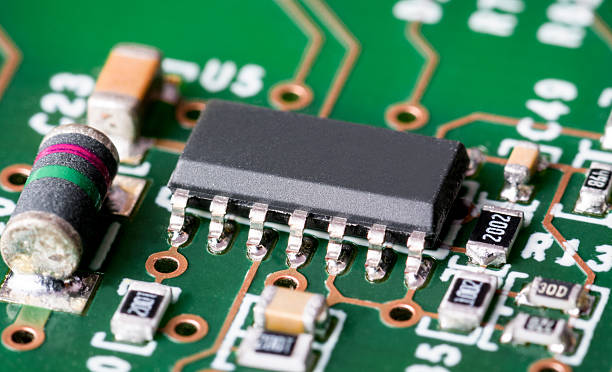

What is the SP 3-872-009 Shut Down Harness?

The SP 3-872-009 Shut Down Harness is an electrical component used in various industrial and automotive applications. It acts as a fail-safe mechanism that disconnects electrical power in case of an emergency or system failure. This harness ensures that machines and vehicles operate safely by preventing overheating, electrical surges, and other hazardous conditions.

Key Features:

- Durable wiring and connectors to withstand harsh environments.

- Fail-safe mechanism to prevent system failures.

- Compatibility with a range of industrial and automotive equipment.

- Easy integration into existing electrical systems.

- Corrosion-resistant materials for long-term reliability.

Applications of the SP 3-872-009 Shut Down Harness

This shut-down harness is widely used in different industries due to its reliability and safety features. Below are some key applications:

1. Automotive Industry

In vehicles, the SP 3-872-009 Shut Down Harness is used to control engine functions, ensuring that if there is an electrical issue, the system safely shuts down to prevent damage. It is particularly useful in:

- Heavy-duty trucks to prevent engine overheating.

- Construction vehicles that require reliable electrical cut-off mechanisms.

- Emergency vehicles to manage electrical loads efficiently.

2. Industrial Machinery

In industrial settings, machines require controlled shutdowns to avoid costly breakdowns. The SP 3-872-009 Shut Down Harness is used in:

- Manufacturing plants to manage electrical circuits.

- Heavy machinery such as forklifts and cranes.

- Generators and backup power systems to prevent overloads.

3. Agricultural Equipment

Farm machinery often operates in demanding conditions. The shut-down harness ensures safety by automatically cutting power when necessary in:

- Tractors and harvesters to avoid overheating.

- Irrigation pumps to prevent electrical surges.

- Automated farming systems for controlled power distribution.

4. Marine and Aerospace Applications

Marine and aerospace industries rely on highly reliable electrical systems. The SP 3-872-009 Shut Down Harness plays a role in:

- Naval vessels and ships to manage electrical safety.

- Aircraft systems where emergency power shutdown is crucial.

- Submersible machines that require water-resistant electrical cut-offs.

Benefits of Using the SP 3-872-009 Shut Down Harness

1. Enhanced Safety

The primary purpose of this harness is to prevent accidents caused by electrical failures. It ensures machinery and vehicles shut down before overheating or circuit failures cause major damage.

2. Increased Equipment Lifespan

By protecting electrical systems from overloads and failures, the shut-down harness extends the operational life of machinery and vehicles.

Also Read: 12230339 Degrading Little Whores 144 Part 2 2240p

3. Efficient Power Management

This harness helps in managing electrical loads effectively, reducing the risk of power surges and ensuring optimal energy consumption.

4. Prevention of Costly Repairs

A failed electrical system can lead to expensive repairs or replacements. The SP 3-872-009 Shut Down Harness minimizes this risk by acting as a protective barrier against sudden failures.

5. Easy Installation and Maintenance

Designed with user convenience in mind, the shut-down harness is relatively easy to install and maintain, making it a cost-effective solution for industries and individuals.

How to Install the SP 3-872-009 Shut Down Harness

Proper installation is crucial to ensure the functionality and safety of the harness. Follow these steps:

Step 1: Gather Necessary Tools

Before installation, ensure you have:

- Wire cutters and strippers

- Crimping tool

- Electrical tape and heat shrink tubing

- Multimeter for testing

Step 2: Identify Connection Points

Locate the power source, control unit, and any emergency shutdown switches that will be linked with the harness.

Step 3: Connect the Harness

- Attach the harness connectors to the designated terminals.

- Ensure all wiring is securely fastened to prevent loose connections.

- Use heat shrink tubing to protect exposed wires.

Step 4: Test the System

- Power on the system and monitor the connection.

- Use a multimeter to check voltage levels.

- Activate the shutdown function to confirm proper operation.

Step 5: Secure the Wiring

- Ensure wires are properly routed to avoid interference with moving parts.

- Use cable ties to keep everything organized.

Troubleshooting Common Issues

Even though the SP 3-872-009 Shut Down Harness is built for reliability, occasional issues may arise. Here are some common problems and solutions:

1. The Harness is Not Triggering the Shutdown

- Check wiring connections to ensure they are properly attached.

- Test the power supply to verify voltage levels.

- Inspect the control unit for any malfunctions.

2. Unexpected Shutdowns Occur

- Look for short circuits or frayed wires.

- Ensure no overloading is causing system failures.

- Check for faulty sensors that may be triggering the shutdown incorrectly.

3. Corrosion or Wear on the Harness

- Regularly inspect the harness for signs of wear and replace it if necessary.

- Use protective coatings to prevent corrosion.

- Keep the connections dry and clean to avoid degradation.

Maintenance Tips for Longevity

To ensure the SP 3-872-009 Shut Down Harness remains in optimal condition, follow these maintenance tips:

- Regular Inspections: Check for frayed wires or loose connections.

- Keep it Clean: Avoid dirt and moisture buildup around the connectors.

- Replace Damaged Parts: If any section of the harness is damaged, replace it immediately.

- Use Proper Storage: When not in use, store the harness in a dry and cool environment.

Conclusion

The SP 3-872-009 Shut Down Harness is an essential safety component for a variety of applications, including automotive, industrial, agricultural, and marine systems. By ensuring a safe and controlled power shutdown, this harness prevents accidents, extends the lifespan of machinery, and improves overall efficiency.

Whether you are installing, maintaining, or troubleshooting this harness, understanding its functions and importance will help you optimize its performance. Investing in quality shutdown harnesses like the SP 3-872-009 is a proactive step toward ensuring operational safety and reliability.

Post Comment